|

1. COD TOC analyser (Nanocolour-400D)

The COD TOC Analyzer (Nano Colour-400D) is used to analyze wastewater, drinking water, surface water, and groundwater containing organic compounds or other impurities. The Chemical Oxygen Demand (COD) test determines the oxygen equivalent required to oxidize organic matter using a strong chemical oxidant. Total Organic Carbon (TOC) measures organic (carbon-based) contaminants in a water system. It is also used to measure various parameters such as extinction, unknown concentrations of liquid samples, and kinetics.

|

|

2.Gas sensor unit

The gas sensor unit is employed to evaluate the performance of thin film sensors exposed to various gases under different operating temperatures. A well-known water displacement method is utilized to measure the gas volume, while a PID controller regulates the temperature. This unit can measure gas responses at temperatures up to 300°C and concentrations as low as 0.011 volume percent. The test dome, constructed from Corning glass, has a volume of 8.5 liters. Samples measuring 1 cm² can be mounted on the hot plate. The system is equipped with a Keithley System Electrometer-6514, a programmable electrometer interfaced with a PC via an RS-232 cable for data acquisition.

|

|

3.IPCE mapping unit

The Incident Photon-to-Current Efficiency (IPCE) mapping unit measures the efficiency of converting incident photon flux into electrical current for absorbed photons within a wavelength range of 360 to 420 nm using LED lamps. Light calibration is performed with a Hamamatsu photodiode, and photocurrent spectra are measured at a constant potential against Ag/AgCl using a potentiostat. IPCE, also known as external quantum efficiency, provides insights into current generation, recombination, and diffusion mechanisms within the cell. A 100% IPCE indicates the generation of one photoelectron for every incident photon.

|

|

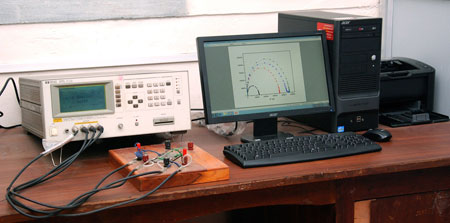

4.Precesion LCR meter (Hewlett Packard, 4284A) (Teacher in charge of PIFC)

The HP 4284A Precision LCR Meter offers a cost-effective solution for accurate and efficient component and material characterization. Its wide frequency range of 20 Hz to 1 MHz and high-precision test signals enable compliance with common industry standards. This LCR meter rapidly measures inductance (L), capacitance (C), and resistance (R) with a speed of 15 ms. It is instrumental in analyzing both bulk and thin film oxide samples. The meter determines capacitance, dielectric loss, real and imaginary impedance components, from which dielectric constant and AC conductivity can be calculated. Additionally, it measures absolute impedance (|Z|), admittance (|Y|), dissipation factor (D), quality factor (Q), equivalent series resistance (Ra), equivalent parallel resistance (Rp), reactance (X), susceptance (B), and phase angle (θ) across a wide range.

|

|

5.Spectroscopic reflectometer (StellarNet USA)

The Spectroscopic Reflectometer is a versatile instrument capable of measuring reflectance, transmittance, and refractive index (n) of thin film materials. By analyzing both reflectance and transmittance data, the instrument accurately determines refractive index. Additionally, it non-destructively measures the thickness of single or multilayer thin film samples within a range of 5 nm to 20 µm with a precision of 10 Å. Equipped with a Sony ILX511 CCD detector, the system captures reflectance spectra across a wavelength range of 190 to 1100 nm. The portable USB spectrometer includes a reflectance probe, halogen and deuterium light sources, and an armored fiber optic cable splitter. StellarNet's SpectraWiz and TF Companion software facilitate calorimetry analysis and enable real-time spectral capture and instrument control for reflectance and transmittance measurements. A comprehensive materials database supports analysis of various substrates and multilayer structures, including freestanding, rough, thick, and thin film configurations.

|

|

6.Spray Pyrolysis Technique for thin film deposition

Spray pyrolysis is a versatile and cost-effective wet chemical method for depositing a wide range of materials as thin films. This technique enables the deposition of films at substrate temperatures up to 500 °C, with adjustable spray rates, concentrations, and substrate-to-nozzle distances. A PID controller maintains precise temperature control, while a 0.5 HP air compressor supplies dry air as a carrier gas for solution atomization. Spray pyrolysis is capable of producing various micro and nanostructures. Optimizing parameters such as substrate temperature, spray rate, carrier gas pressure, and nozzle-to-substrate distance enhances film deposition efficiency and quality.

|

|

7.System electrometer (Keithley model 6514)

The Keithley Model 6514 System Electrometer is an advanced instrument capable of high-resolution, rapid measurements of current, voltage, and charge. Its built-in IEEE-488, RS-232, and digital I/O interfaces facilitate seamless integration with computers. Designed for applications demanding precise and swift measurements of low currents, voltages from high-resistance sources, and charges, the electrometer excels in delivering accurate data. It can be coupled with various equipment, including gas sensing units and UV-Vis photodetectors, to measure currents generated by light detectors or high resistances of metal oxides upon gas adsorption. The electrometer offers a wide measurement range, enabling resistance measurement from a few ohms to 210 GΩ, current sensitivity from 20 pA to 20 mA, and charge measurement from 20 fC to 20 µC with exceptional resolution. Additionally, it allows for rapid measurements of resistance, charge, or current at intervals ranging from milliseconds to seconds.

|

|

8. XRD, Bruker, D2 Phaser (Teacher in charge of PIFC)

The Bruker D2 Phaser is a compact X-ray diffractometer designed for polycrystalline material analysis. Its advanced LYNXEYE detector enables rapid acquisition of high-quality X-ray powder diffraction data. Employing a copper target, the system generates X-rays with a wavelength of 1.5406 Å. This versatile instrument excels in phase identification, crystallite size and strain determination, and structural refinement. It offers a 2θ scanning range from 3° to 160° with an accuracy of 0.02° and a minimum peak width of less than 0.05°. The D2 Phaser utilizes DIFFRAC.SUITE software for data acquisition and analysis, complemented by the ICDD PDF4 database for comprehensive crystallographic information.

|

|

9.Double Distilled Water Plant

This compact double distilled water plant produces 2 liters of highly purified and disinfected water per hour. Equipped with dual safety cut-outs and automated sensors for water level and condenser flow, the system ensures reliable operation. The distillation process effectively removes minerals, microorganisms, and reduces chemical contaminants, making the water suitable for research applications. Powered by a 4 kW silicon heater, the plant utilizes two 4-liter quartz glass containers for the distillation process.

|

|

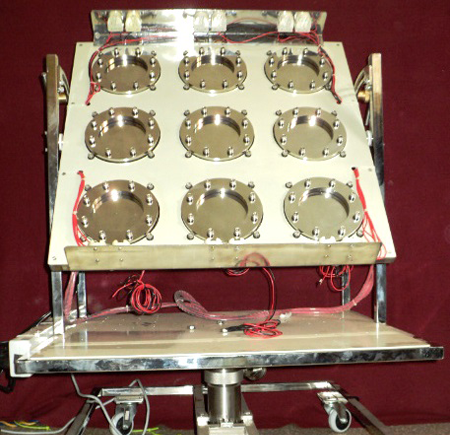

10.PEC degradation reactor

The PEC detoxification reactor module effectively eliminates water contaminants including aromatic compounds, pesticides, organic dyes, sulfur compounds, and bacteria, which are challenging to remove using conventional physical methods. The system comprises nine photoelectrochemical cells, each equipped with a photoelectrode attached to a steel disc. A peristaltic pump circulates contaminated water through these cells via silicon tubes. Applying an electrical bias enhances efficiency by reducing electron-hole pair recombination. Reactor modules are arranged in series, with the outlet of one serving as the inlet for the next. The final output is collected from the ninth reactor. The photoelectrode (cathode) and steel disc maintain a 0.1 cm distance, and the electrode's contact area with the electrolyte measures 64 cm². A peristaltic pump circulates the electrolyte solution of desired concentration through the reactor at the required flow rate under sunlight.

|

|

11.PE loop tracer system

The PE Loop Tracer system, a fully digital instrument interfaced with a computer via RS232 from Marine India Company, offers automated operation and PC control. It facilitates various tests, including: (i) PE Loop Measurements: Analyze the behavior of a polymeric material (PE) loop at different temperatures and frequencies. (ii) Fatigue Testing: Evaluate the material's endurance under cyclic loading conditions up to the 20th order. The system applies a wide range of electric fields (up to 50 kV/cm for 0.5 mm bulk pellets) and frequencies (50 Hz to 1 kHz in eight fixed steps). A PID controller ensures precise temperature control, with silicon oil facilitating uniform heating of the samples. The PE Loop Tracer measures the hysteresis curve, which depicts the relationship between the applied electric field and the resulting polarization (electrical dipole moment) in the material. This phenomenon is commonly observed in ferroelectric materials, where the polarization organizes into domains similar to magnetic domains.

|

|

12.UV-VIS spectrophotometer 3000+

The UV-VIS Spectrophotometer 3000+ measures the transmittance properties of both films and liquids across a wavelength range of 300 to 1000 nm. Its double-beam optical system ensures stability and facilitates easy referencing. The spectrophotometer interfaces with a computer via UVWin software, enabling advanced data analysis. An eight-position sample holder allows for simultaneous measurement of multiple samples. Equipped with a holographic grating, the instrument minimizes stray light, enhancing measurement accuracy. It boasts a rapid scanning speed of 300-1000 nm at rates from 0.1 to 10 nm per second. The spectrophotometer measures absorbance values between +3 and -3. A deuterium lamp and a tungsten lamp serve as light sources, while a silicon photodiode detects the light.

|

|

13.Elico SL207 mini spectrophotometer

The Elico SL207 Mini Spectrophotometer quantifies the transmittance properties of materials across a wavelength range of 335 to 1000 nm with an accuracy of ±1 nm. It measures absorbance values from 0 to 1.999 Abs. A tungsten halogen lamp serves as the light source, while a silicon photodiode detects the transmitted light. A Crenzy Turner monochromator ensures stability and rapid readings. The spectrophotometer accommodates two samples simultaneously using a manual cuvette holder. A microcontroller-driven motorized wavelength drive enhances accuracy.

|

|

14.COD digester

The COD digester is a thermal reactor designed for sample digestion. Equipped with a solid-state heating unit and a precise temperature controller, it maintains a constant digestion temperature between ambient and 250 °C. The unit accommodates 25 samples simultaneously using 16 mm diameter closed-cap vials. An integrated fan accelerates cooling for rapid subsequent measurements. The digester offers programmable operation for durations of 0 to 24 hours.

|

|

15.Spectroscopic Ellipsometer (Teacher in charge of PIFC)

A spectroscopic ellipsometer is an optical technique used to determine material properties such as refractive index (n), extinction coefficient (k), and complex dielectric function. It measures changes in the polarization state of light upon reflection or transmission from a sample. These changes are quantified as amplitude ratio (Psi) and phase difference (Delta) across a wavelength range of 300 to 900 nm. The Alpha-SE ellipsometer employs a visible light source and can analyze samples at various angles of incidence (65°, 70°, 75°). It also supports transmission mode measurements at 90°. By modeling experimental data, the instrument accurately determines physical parameters like film thickness and roughness.

|

|

16. Photochemical Reactor

This photochemical reactor is designed to study the degradation of harmful pollutants using a powder catalysis method. A quartz chamber houses the reaction mixture, while a 200W UV lamp positioned above it emits ultraviolet radiation to initiate the process. To expand the light source, the reactor also includes two LEDs and a tungsten halogen lamp for visible light catalysis. A cooling system, connected to the UV lamp jacket via flexible silicon pipes, maintains optimal reaction temperatures. A magnetic stirrer ensures continuous agitation of the dye solution during the degradation process.

|